Exploring Aluminum Metal Casting: Premium Robust Parts for Manufacturing and Industry

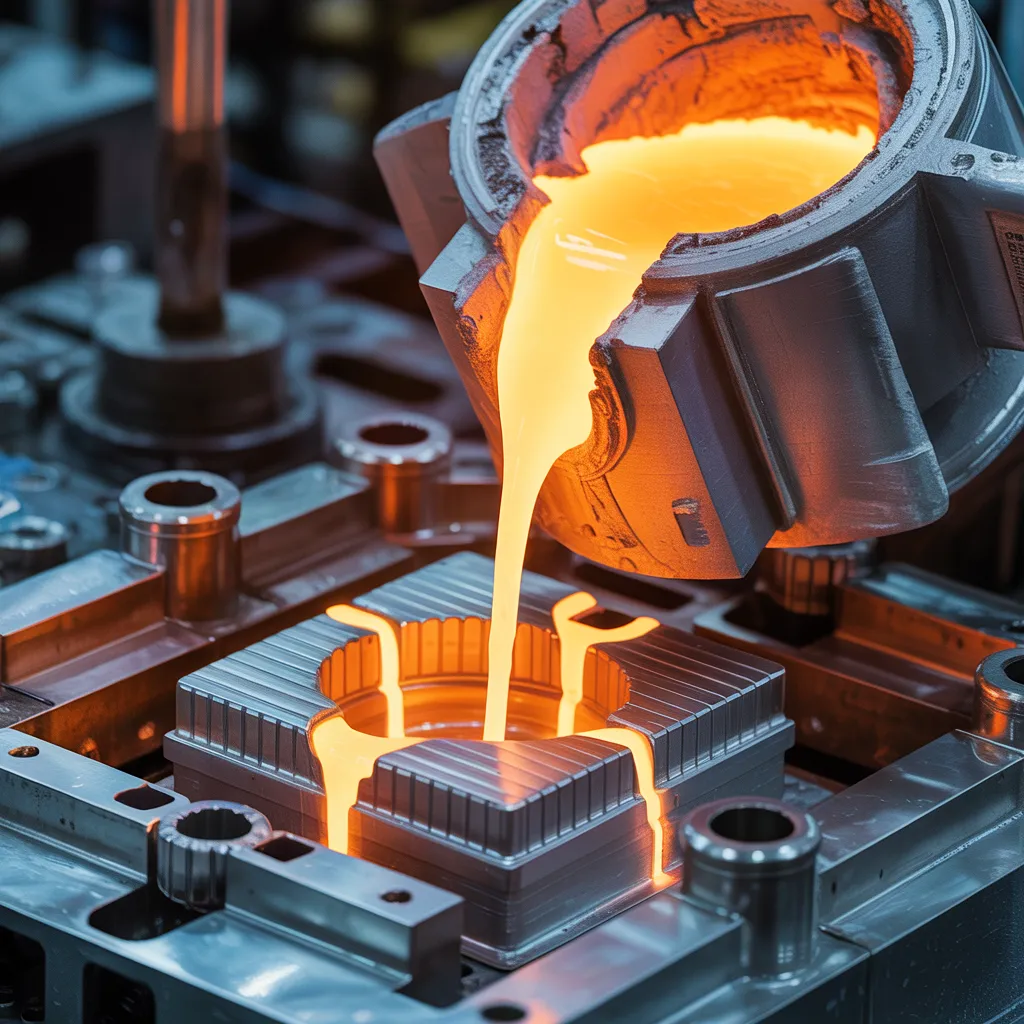

Aluminum metal casting holds a vital position in contemporary manufacturing. It offers manufacturers the capacity to manufacture strong, lightweight components that can enhance overall product performance. Various techniques, from sand to die casting, provide design flexibility and precision. Understanding the nuances of alloy selection and production methods can substantially impact the results. As industries evolve, so do the obstacles and innovations in aluminum casting. What strategies can improve efficiency and quality in this essential process?

How Aluminum Casting Enhances Your Manufacturing Process

Aluminum casting provides many benefits that can greatly enhance the manufacturing process. Its low-weight characteristics allows for the production of parts that are simpler to manage and move, ultimately minimizing operational costs. Additionally, aluminum offers exceptional corrosion resistance, increasing the lifespan of components in multiple environments. The excellent thermal and electrical conductivity of aluminum makes it ideal for applications in the automotive and electronics sectors, where heat dissipation is essential.

Moreover, aluminum can be readily molded into complex shapes, allowing for intricate designs that fulfill specific engineering needs. The process also enables reduced tooling costs and shorter lead times, which is critical in today's fast-paced market. Furthermore, the recyclability of aluminum promotes sustainability efforts, making it an eco-friendly choice. All in all, these benefits position aluminum casting as a beneficial technique that can greatly increase efficiency and product quality in manufacturing.

Frequent Methods Applied in Aluminum Metal Casting

Aluminum metal casting utilizes different methods that meet diverse manufacturing requirements. Two prevalent methods are die casting and sand casting, each providing unique advantages and applications. Knowledge of these processes is vital for optimizing production efficiency and attaining optimal final products.

Sand Casting Techniques

A variety of sand casting methods are regularly applied in the aluminum metal casting process, all offering unique strengths depending on the project's specifications. The most widely used technique is green sand casting, which incorporates a mixture of sand, clay, and water. This method ensures excellent moldability and is cost-effective for small to medium production runs. Another technique, called resin sand casting, integrates resin into the sand mixture, enhancing the mold's strength and surface finish. Furthermore, shell molding entails creating a thin shell of sand and resin around a pattern, enabling better dimensional accuracy and smoother surfaces. Each technique is determined based on factors such as production volume, complexity of the part, and desired finish quality.

Die Casting Techniques

Various die casting methods are used in the aluminum metal casting industry, each adapted to meet specific production needs and design complexities. The two primary approaches are hot chamber and cold chamber die casting. Hot chamber die casting is well-suited for low-melting-point metals and allows for rapid production cycles, making it efficient for high-volume manufacturing. In contrast, cold chamber die casting is optimal for aluminum and other high-melting-point alloys; it entails injecting molten metal into cold molds, providing greater control over the metal's properties. In addition, pressure die casting delivers uniformity and precision in the final product, while vacuum die casting reduces gas entrapment, enhancing part integrity. Each approach offers distinct benefits, making them crucial for different industrial applications.

Picking the Appropriate Aluminum Alloys for Casting

Selecting the suitable aluminum alloy for casting is essential, as alloy composition directly affects the final product's properties. Compatibility considerations with the preferred casting process also plays a significant role in achieving intended outcomes. Moreover, understanding the mechanical properties of various alloys can guide decision-making to meet precise application requirements.

The Importance of Alloy Composition

Selecting the appropriate aluminum alloy is essential for achieving ideal performance in casting applications. The composition of aluminum alloys greatly influences their mechanical properties, corrosion resistance, and thermal conductivity. Common alloying elements, such as silicon, copper, and magnesium, are added to improve certain characteristics like strength and ductility. For example, silicon increases fluidity, making it excellent for intricate castings, while magnesium increases strength, making alloys ideal for structural components. Understanding the composition enables manufacturers to pick alloys that fulfill the particular needs of the application, whether it be for automotive parts or industrial machinery. In the end, the right alloy composition not only ensures durability but also optimizes production efficiency and cost-effectiveness detailed guide in the casting process.

Casting Method Compatibility

Grasping alloy composition is merely one aspect of improving aluminum casting; the compatibility of the chosen alloy with specific casting processes is equally important. Different casting techniques, such as sand casting, die casting, and permanent mold casting, require distinct alloy properties to achieve optimal results. For example, die casting often works best with alloys with lower melting points and excellent fluidity, while sand casting may use alloys that exhibit good strength and ductility. Furthermore, the thermal and mechanical properties of the alloy must match the requirements of the selected process to reduce defects and maintain dimensional accuracy. Finally, selecting the right aluminum alloy based on casting process compatibility is vital for producing high-quality, durable components customized for industry needs.

Mechanical Properties Overview

The mechanical characteristics of aluminum alloys are fundamentally important in identifying their fitness for different casting purposes. These attributes, featuring tensile strength, ductility, hardness, and fatigue resistance, are key determinants in picking the correct alloy for specialized industrial demands. Alloys such as 356 and 319 enjoy preference for their exceptional castability and mechanical functionality, positioning them as ideal for automotive and aerospace constituents. Additionally, the choice of alloy can affect corrosion resistance and thermal conductivity, which are fundamental in many applications. Grasping the tradeoff between strength and weight is also vital, because different alloys present variable performance standards. Finally, choosing the suitable aluminum alloy ensures that cast parts satisfy the stringent specifications of their planned application.

Advice for Quality Aluminum Casting Work

Successful aluminum casting projects demand thorough planning and attention to detail. First, it is vital to select the appropriate aluminum alloy depending on the desired mechanical properties and application specifications. Appropriate mold design is imperative; molds should be constructed to facilitate smooth metal flow and minimize defects. Additionally, maintaining consistent temperatures throughout the casting process is essential for achieving consistent results.

Acquiring high-quality equipment, including furnaces and pouring systems, can substantially influence the outcome. It is also wise to conduct thorough pre-casting inspections to discover potential issues.

Furthermore, implementing a structured quality control process ensures that the final products satisfy industry standards. Finally, documenting each step of the process allows for enhanced analysis and improvement in future projects. By following these guidelines, manufacturers can improve the efficiency and success of their aluminum casting endeavors.

Addressing Typical Aluminum Casting Defects

With careful design and execution, aluminum casting processes can encounter numerous problems that may affect the finished casting. Frequent challenges consist of porosity, which stems from trapped gases during the pouring process, causing weak spots in the casting. To remedy this, it is essential to adjust the melting temperature and guarantee proper venting in casting molds.

A further recurring issue is dimensional inconsistency, often caused by thermal contraction or improper mold alignment. Consistent mold adjustment and exact temperature regulation can mitigate these discrepancies.

Surface defects such as roughness or inclusions can arise from contamination or insufficient surface preparation. Employing thorough cleaning and degreasing procedures is essential to attaining a smooth finish.

Lastly, inadequate filling may cause incomplete castings. Making certain of adequate pouring speed and employing suitable gating designs can help achieve better mold filling and total casting quality.

Recent Advances in Aluminum Casting Approaches

As industrial sectors progress, latest developments in aluminum casting techniques are revolutionizing manufacturing processes. Advanced technologies such as 3D printing have emerged, allowing the creation of sophisticated shapes and reducing lead times substantially. This technique allows for rapid prototyping and customization, synchronizing production with individual client demands.

Moreover, the integration of digital modeling facilitates accurate mold design, boosting accuracy and minimizing material waste. Techniques like vacuum die casting and squeeze casting are becoming more popular, delivering improved mechanical properties and surface finishes.

Furthermore, advancements in alloy development are leading to lighter while maintaining strength in aluminum materials, broadening their applicability across various sectors. Automated systems and robotics in the casting process enhance operations, enhancing efficiency and lowering labor costs. Combined, these innovations are defining new standards in aluminum casting, elevating product quality and sustainability while fulfilling the growing demands of modern industries.

Practical Applications of Aluminum Cast Parts in Industrial Sectors

The developments in aluminum casting technologies have significantly extended the scope of applications across numerous industries. In the automotive sector, aluminum cast pieces are used for engine blocks, transmission housings, and wheels, supporting vehicle lightweighting and improved fuel efficiency. Aerospace manufacturers favor aluminum castings for structural components based on their strength-to-weight ratio, increasing performance without undermining safety.

Within the electronics sector, aluminum casings are widely used for devices, delivering protection while efficiently managing heat dissipation. Additionally, the construction sector utilizes aluminum cast parts in window frames, roofing, and architectural elements, taking advantage of their durability and resistance to corrosion.

Additionally, the energy sector utilizes aluminum castings for turbine housings and other vital components, ensuring reliability in demanding environments. Overall, the versatility of aluminum cast parts consistently drives innovation and efficiency across various industries, displaying their crucial role in modern manufacturing.

Popular Questions

What Safety Measures Should Be Implemented During Aluminum Casting?

Throughout aluminum casting, individuals should put on protective gear, provide proper ventilation, handle molten metal with care, keep a clean workspace, use safety equipment like gloves and goggles, and stay alert to potential fire hazards.

How Can the Surface Finish of Aluminum Castings Be Enhanced?

To better the surface finish of aluminum castings, one can utilize methods such as enhancing mold design, utilizing finer sand for casting, maintaining appropriate cooling rates, and using post-casting treatments for example sandblasting or polishing.

Which Equipment Is Needed for Small-Scale Aluminum Casting?

Key equipment for small-scale aluminum casting includes a furnace for melting, molds for structuring, a ladle for casting, safety gear for protection, and tools for post-casting work. These pieces of equipment ensure quality and efficient production in smaller operations.

How Can Environmental Regulations Affect Aluminum Casting Operations?

Regulatory requirements greatly impact aluminum casting operations by setting constraints on emissions, waste management, and resource usage. Conformity commonly calls for investment in eco-friendly technologies, which can elevate operational costs but ultimately promote sustainability and public health.

What Are the Costs of Establishing Aluminum Casting Facilities?

Establishing aluminum casting plants generates various costs, including equipment acquisition, facility construction, raw materials, labor, and compliance with environmental standards. These expenditures can significantly affect upfront investment and continuous operational budgets for manufacturers.